story by Ava Huelskamp | graphic by Natalie Mazey | photography by Alexandra Fernholz | art by Kelly Johantges

In the wake of a devastating pandemic plaguing the world, walking into the fluorescent-lit aisles of grocery stores that used to be stockpiled with cleaning supplies, toilet paper, or disinfectant wipes has become the equivalent of walking into a barren desert.

The coronavirus, or COVID-19, has symptoms described by the Center for Disease Control (CDC) as “fever, coughing, shortness of breath, chills, repeated shaking with chills, muscle pain, headache, sore throat, or new loss of taste or smell.” As the virus began to grip China by the neck in late 2019, it quickly spread to the rest of the world, including Butler County, and in the past few months has affected the lives of thousands.

A big repercussion of the deadly disease has been the shortage of protective supplies in hospitals and homes, like toilet paper, masks, hand sanitizer, and wipes. Out of 158 East students surveyed, 97.5% say they’ve noticed a smaller or depleted supply of these items at the store.

The increase in demand of certain products has placed a strain on the supply chain, which Peter Lukszys, professor of Supply Chain Management at the University of Wisconsin, told Spark can be attributed to the fall of China at the feet of the virus first.

“A lot of our goods in the U.S. come from overseas from places like China and other foreign countries. When [China was] hit by COVID-19 first, many of their factories shut down,” Lukszys says. “That impacted the supply side of the supply chain, and the demand side was also impacted because China is one of the largest economies [in the world].”

University of Wisconsin Supply Chain Management Professor John McKeller expects the high demand for products as a result of COVID-19 to change the algorithm of supply chains and make consumers re-evaluate where they’re sourcing their products from.

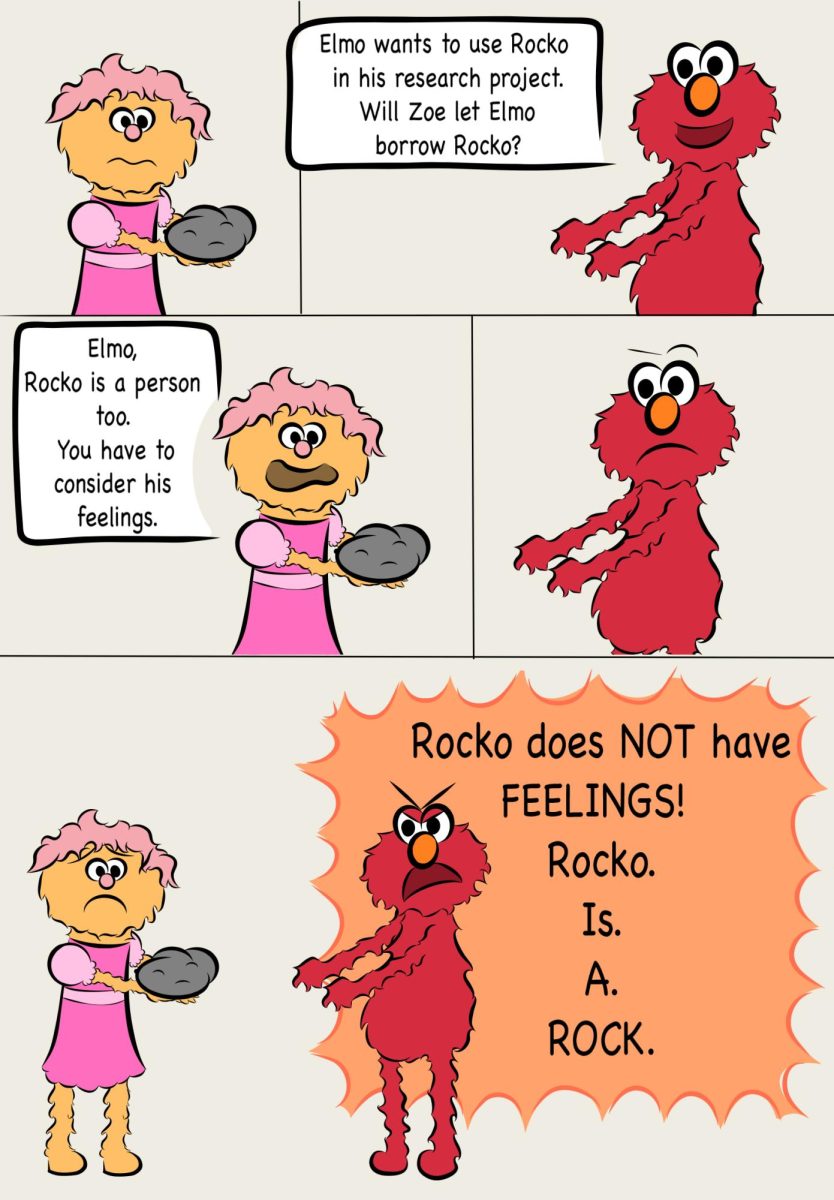

“People will realize that your supply chain is only as resilient as the weakest link in it,” McKeller told Spark.

In response to the low number of supplies available in stores, people have turned to online sites to attempt to get their supplies, with 47.5% of 158 East students surveyed saying their family has ordered supplies online.

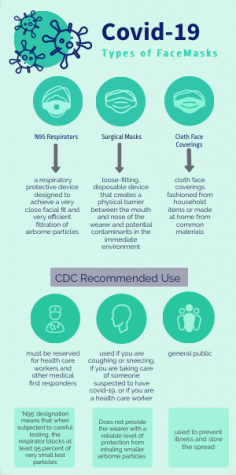

Even more so than the supply shortages in grocery stores for everyday citizens, hospitals around the world are struggling to keep Personal Protective Equipment (PPE) that is needed for COVID-19 patients and the medical personnel caring for them in stock.

Christina Salyers, a nurse in the Neonatal Intensive Care Unit (NICU) at Cincinnati Children’s Hospital says Children’s has not run out of the supplies they need as of the beginning of April, but no one knows what could happen in the future. She knows that supplies are scarce, and it puts lots of pressure on all Children’s employees.

“I have been told we have what we need to protect us at this time, but of course, that changes every single day,” Salyers says. “Children’s, along with every other hospital in the tri-state, is monitoring all of their PPE. They’re finding ways to preserve it as much as possible.”

One way Children’s has been trying to preserve their supplies is to have their nurses clean and re-use the PPE they wear during their shift.

“Our eye shields are cleaned off at the end of our shift and then we wear them on every shift that we work, so we don’t get a new pair of eye goggles every day,” Salyers says. “We do get a new mask every day, and that’s just a regular basic mask.”

Spirit Homecare Administrator Sajjad Khan has felt stress about getting enough supplies for his hospital, as the hospital has COVID-19 patients in their care.

“[N-95 masks] are almost impossible to find. I had to go on eBay and buy them at a very high price,” Khan told Spark. “Normally they cost around 70 to 80 cents per mask. I had to buy them on eBay for between $11-$15.”

Battelle, a Columbus-based non-profit organization, has tried to do its part during the pandemic by creating technology to sterilize the essential N-95 respirator masks needed for COVID-19 patients.

Battelle says the company is able to sterilize up to 80,000 masks per machine per day, with two operating machines in Ohio sterilizing a total of 160,000 masks per day.

Salyers is not aware if Children’s is using the new Battelle technology to sterilize masks, but says all hospitals in the Liberty Township area currently have enough supplies, and though the number of cases changes every day, the problem is thankfully not as large in Ohio as other states.

“When you see New York, their hospitals have been full, they are having a very high influx of patients,” Salyers says. “A lot of them are positive for COVID-19 or suspected COVID-19. Those types of hospitals are the hospitals that are having the biggest issues.”

Ohio Gov. Mike DeWine has been providing daily updates on all things COVID-19 on The Ohio Channel, Facebook Live, and his twitter account, including PPE shortages in hospitals. Based on his tweets, the governor seems to feel anxious about the current state of Ohio’s PPE.

“I want to make a public plea to everyone using these [N-95] masks-every mask is precious. Please do not throw them away,” DeWine said on Twitter. “We can reuse them up to 20x because of this Battelle technology. When you throw a mask away, you are depriving someone else of having a mask, because we only have so many.”

According to Salyers, repercussions could be deadly if hospitals were to run out of supplies, which would put nurses like herself at risk.

“[Instead of] using PPE for one patient and disposing of it, you would have to probably reuse it multiple times,” Salyers says. “The worst part of that would be cross contamination. You would definitely be spreading COVID-19. [Reusing supplies] would also risk other patients getting COVID-19, as well as staff.”

Khan has friends also in the medical field who are experiencing some of these possibly deadly repercussions first hand.

“[My friends] have mentioned that they are not able to get any supplies at all. They don’t have any masks. They don’t have anything to treat [COVID-19] patients,” Khan says. “I’ve [also] been reading about nurses in [some] hospitals being asked to treat patients without an N-95 mask. The repercussions for [these nurses] is that they are putting themselves in danger to help patients.”

The supply chain is expected to take a while to catch up, considering the impact COVID-19 had on China that caused factories to shut down and workers to stay home.

“Because a lot of the factories were in China and they just came back online slowly -[the] Chinese government sent back their employees March 11, 2020-they’re still not at full capacity, and will not be for a while,” Lukszys says. “A lot of [supplies] are being air shipped over [to the U.S.]. That’s not as much the constraint of transportation as one of the constraints of manufacturing. It’s limiting getting goods.”

Despite the risks that come with enough protective supplies being at the ready for sick patients, there seems to be a silver lining. Members of Khan’s community have seen the need for masks and stepped in to try to help, which warmed his heart.

“Our county was kind enough to donate some masks to us,” Khan says. “That was a big help. I’m very grateful to Butler County [citizens] for doing that.”